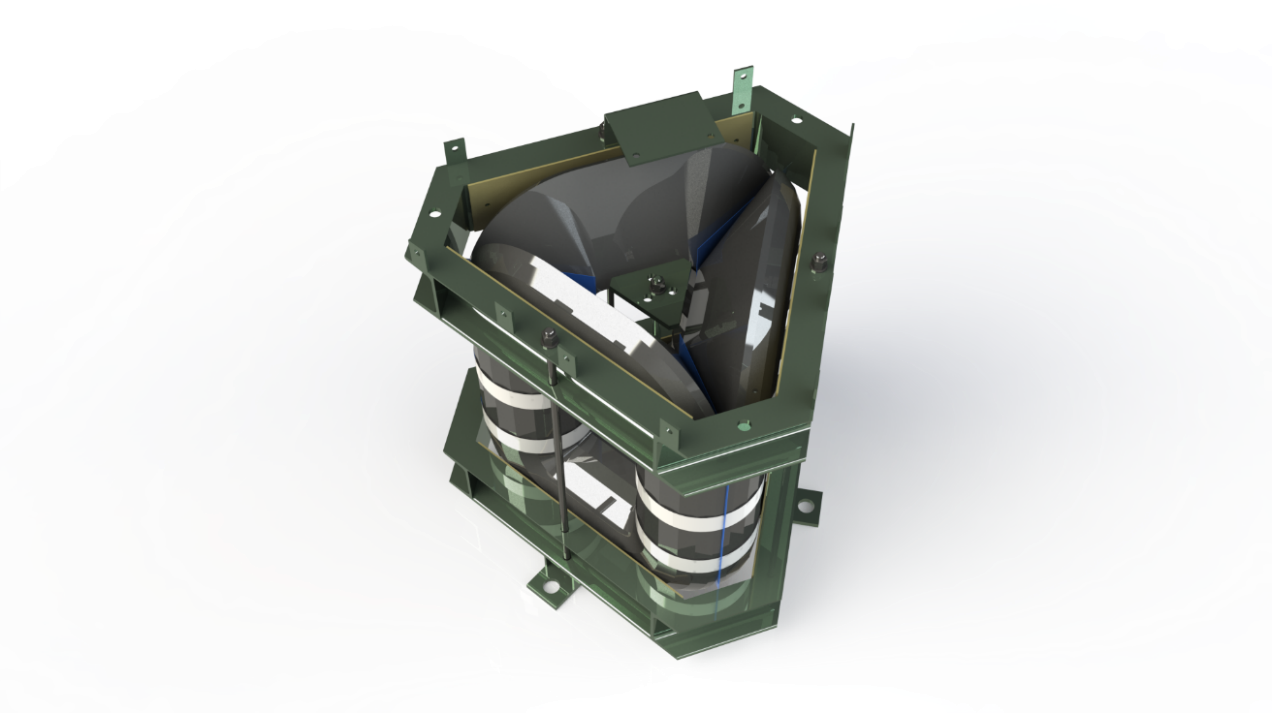

S20 high energy efficiency triangular 3D wound core

In the power system, the iron core is the basic skeleton of the transformer, mainly responsible for enhancing the magnetic field for effective energy conversion in the transformer. Its high magnetic conductivity and low electrical resistance enable it to effectively concentrate and enhance magnetic fields, thereby improving the efficiency of transformers and reducing energy losses.

It has digital factory production and internationally advanced fully automatic intelligent production lines. The system layout includes 3 rewinding lines, 3 longitudinal cutting lines, 11 transverse cutting lines (maximum cutting width 1020mm), 6 stacking lines, test lines and three-dimensional warehouses for core bars and column materials. Material transportation is carried out through AGV carts, RGV carts, roller conveyor lines, etc., and supporting information systems such as ERP, WMS, MES are built to achieve full process, efficient, and refined control of iron core products from raw materials to finished products.

It has the advantages of high processing accuracy, small burrs, good flatness, high efficiency, low loss, low noise, low no-load current, high mechanical strength, strong short-circuit resistance, small partial discharge, good insulation performance, good thermal stability, precise size, excellent process coefficient, and beautiful appearance.